The ISGS X-ray Diffraction (XRD) and X-ray Fluorescence (XRF) Laboratories provide mineralogical and elemental analysis of soils, sediments, and other geological or industrial samples, including mineral phase identification, quantification, and the determination of elemental composition in solid specimens. We specialize in clay mineral research especially the investigation of smectites, illites, mixed-layer clay minerals, I/S, kaolinites, and other clay minerals.

The ISGS X-ray Diffraction (XRD) and X-ray Fluorescence (XRF) Laboratories provide mineralogical and elemental analysis of soils, sediments, and other geological or industrial samples, including mineral phase identification, quantification, and the determination of elemental composition in solid specimens. We specialize in clay mineral research especially the investigation of smectites, illites, mixed-layer clay minerals, I/S, kaolinites, and other clay minerals.

Associate Mineralogist

XRD/XRF Lab Manager

NRB 313

mpentrak@illinois.edu

217-300-5625

Before submitting any samples, please contact the lab manager, Martin P. Pentrak, at mpentrak@illinois.edu, to discuss sample type, quantity, and analytical needs. Upon agreement, complete and submit a sample submission form which should also be included in the shipment.

Samples can be mailed to:

Illinois State Geological Survey

ATTN: Martin P. Pentrak

615 E. Peabody Drive

Champaign, IL 61820

For internal samples, please coordinate drop off with the lab manager.

- Samples must be clearly labeled.

- Specify if you wish samples to be returned to you. If so, include a FedEx or UPS account number in your correspondence. Samples will be stored for up to 1 year after results have been reported.

Rates (costs per sample analysis)

Services are provided at an internal rate for the University of Illinois and at an external rate for other researchers. For more information, contact Martin P. Pentrak, the XRD and XRF lab manager.

| XRD* | Bulk Powder XBP | Bulk Powder (McCrone) MBP | Clay Fraction (< 2μm) 2CLAY | Clay Fraction (<16 μm) 16CLAY |

|---|---|---|---|---|

| Internal | $48 | $66 | $59 | $77 |

| External | $63 | $86 | $77 | $102 |

| * all rates include sample preparation, measurement, data analysis, consultation | ||||

| XRF | Bulk (solid) | Powder/Liquid† | Pressed Pellet | Sample Preparation* |

|---|---|---|---|---|

| Internal | $41 | $43 | $77 | $39 |

| External | $53 | $57 | $101 | $51 |

| * i.e., crushing, grinding, and sieving † rate includes analysis of liquid samples |

||||

Billing & Payment

- Internal: Please make sure that you have the University of Illinois account (CFOPA).

- External: If you do not have a University of Illinois account, please fill out the GAR form and email it to aroperations@illinois.edu, Karen Hartman (khartman@illinois.edu), and Martin P. Pentrak (mpentrak@illinois.edu).

XRD Lab

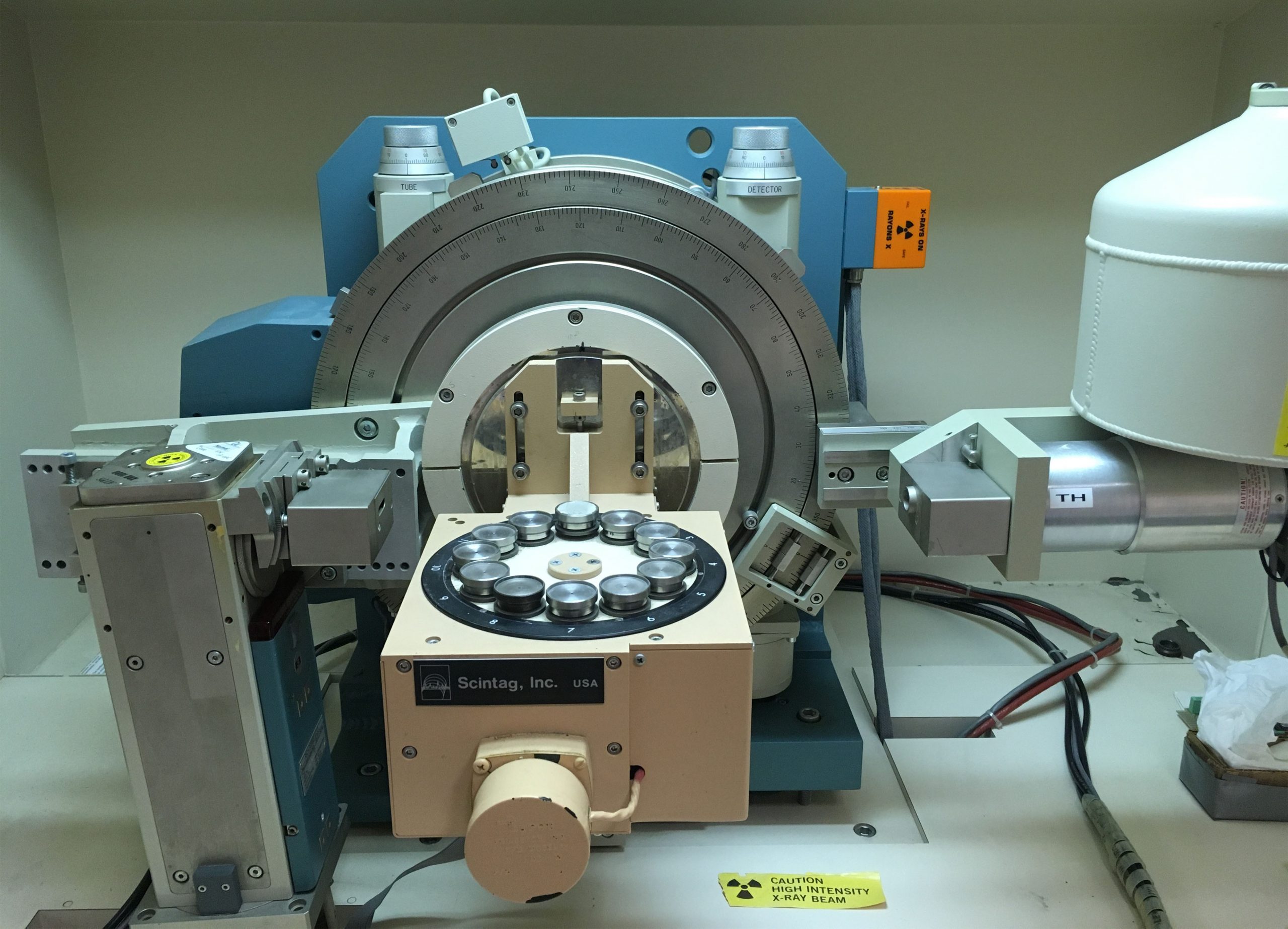

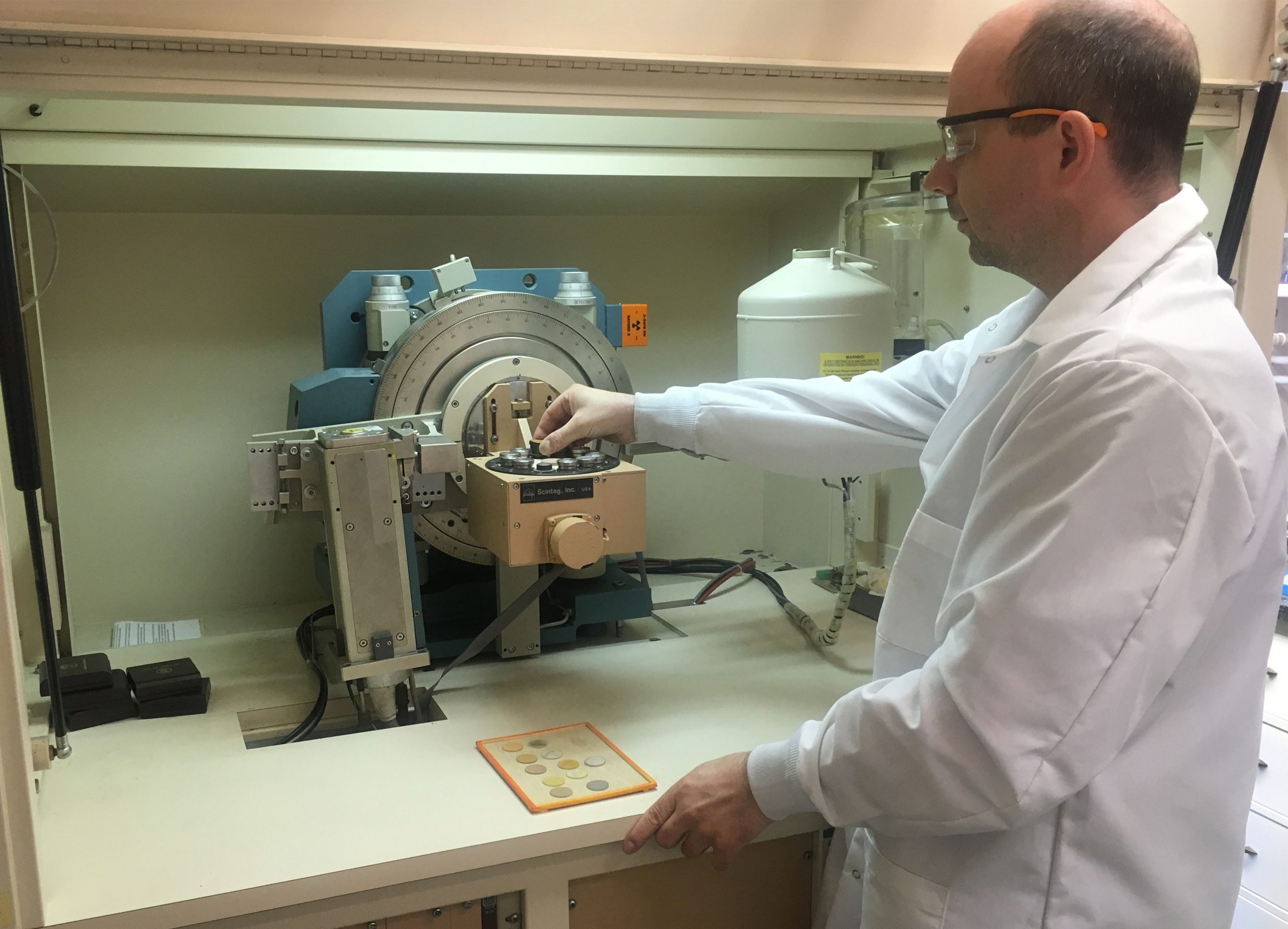

Scintag® XDS2000

Scintag® XDS2000

- Multi-purpose powder diffractometer.

- Bragg-Brenttano Theta-Theta configuration.

- X-ray Powder Diffraction (XRPD) analysis.

- XRD analysis for oriented patterns (films).

- Qualitative analysis – mineral phase identification.

- Quantitative analysis – semi-quantitative analysis, Rietveld refinement.

XRF Lab

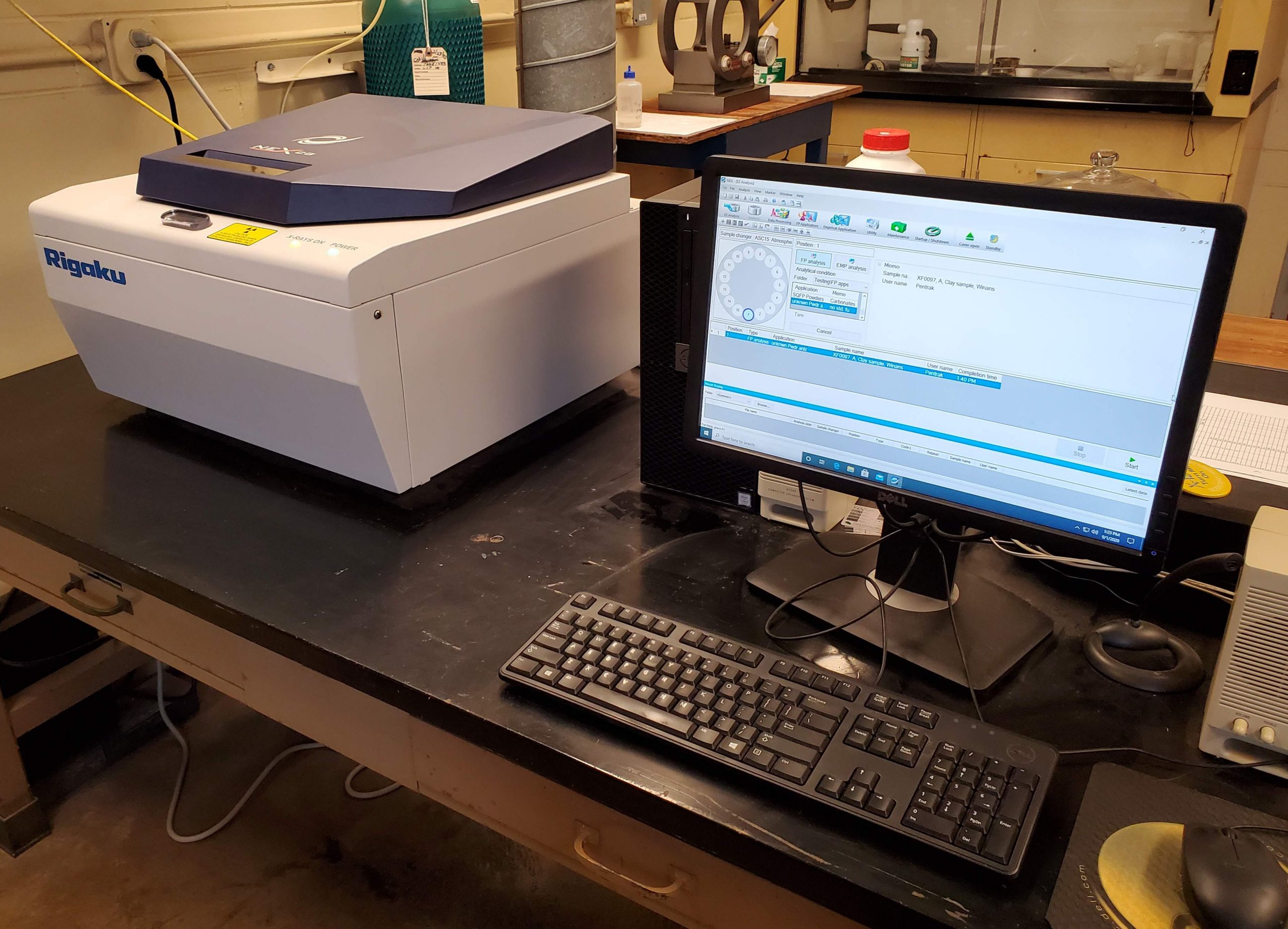

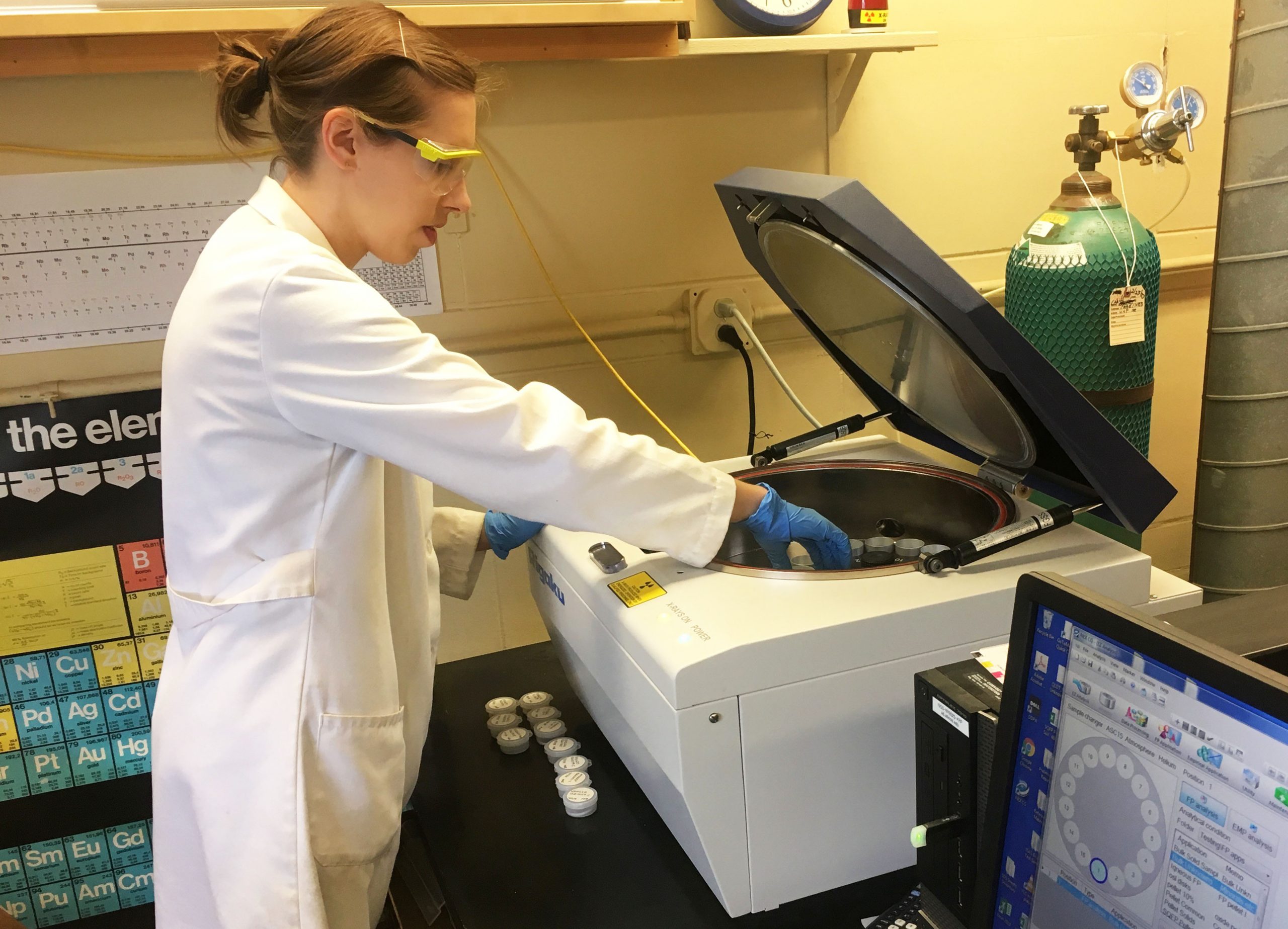

Rigaku NEX CG

- Energy Dispersive X-Ray Fluorescence (ED-XRF) facility.

- A custom ED-XRF system with a high-performance silicon drift detector.

- Quantification of elemental concentrations of sodium to uranium (parts per million).

- Samples measured as solids, powders, or pellets (mixed with organic binder).

Grinding Options

Shatterbox

- Sample size reduction: 1 mm – 0.1 mm.

- Alumina ceramic grinding container.

McCrone micronizing mill

- Sample size reduction: 0.5 mm – 5 μm.

- Forty-eight cylindrical grinding elements (agate, corundum) placed into the grinding jar in eight rows of six elements each.

Samples and Services

We provide the qualitative and quantitative XRD analysis of powders and oriented clay films. The XRF analysis of solid samples (bulk, powder, pressed pellet) delivers the elemental composition of analyzed specimens.

X-Ray Diffraction (XRD)

Bulk Powder Analysis (BPA) of whole rock samples is suitable for quick mineral identification. Samples can be ground in an agate dish (XBP) or micronized by McCrone Mill (MBP) to obtain the desired particle size distribution (< 10 μm).

Recommendation

- 5 g of a dry powdered sample of < 250 μm size fraction is preferred. If samples are delivered wet and bulky, additional preparation steps (drying, grinding, or sieving) prolong the analysis.

- If the sample is already finely ground upon receipt, it is gently disintegrated in an agate dish before installation in the sample tray (XBP rate).

- The average turnaround time for BPA analysis is two weeks per 10 samples.

Methodology

XBP: 3-5 g of the sample (< 250 μm) is ground in an agate dish before installation in the sample tray. Step-scanned data is collected from 5° to 70° 2θ with a fixed rate of 1° per minute with a step size of 0.02°2θ.

MBP: 3-5 g of the sample (< 250 μm) is mixed with 10 mL of propylene alcohol and then micronized for 10 minutes in McCrone Mill. The sample suspension is rinsed from the grinding jar, centrifuged, decanted, and dried in an oven at 70 °C overnight. Once in powdered form, the sample is packed into a sample tray and analyzed by XRD. Step-scanned data is collected from 5° to 70° 2θ with a fixed rate of 1° per minute with a step size of 0.02°2θ.

Results

- The XRD (XBP, MBP) analysis provides qualitative (mineral phase identification) based on the location and intensity of peaks of the 2θ scale compared with the PDF2 database using Materials Data Inc. (MDI) known as JADE.

- The Quantitative XRD analysis is based on the Rietveld refinement and the semi-quantitative analysis.

< 2 μm Clay Mineral Analysis (2CLAY)

Used mainly for the identification of clay minerals from Quarternary – age deposits, shales, and soils.

Recommendation

- 15 g of a dry homogenized powdered sample of < 250 μm size fraction is preferred. If samples are delivered wet and bulky, additional sample preparation steps (drying, grinding, or sieving) prolong the analysis.

- The average turnaround time for 2CLAY analysis is two weeks per 10 samples.

Methodology

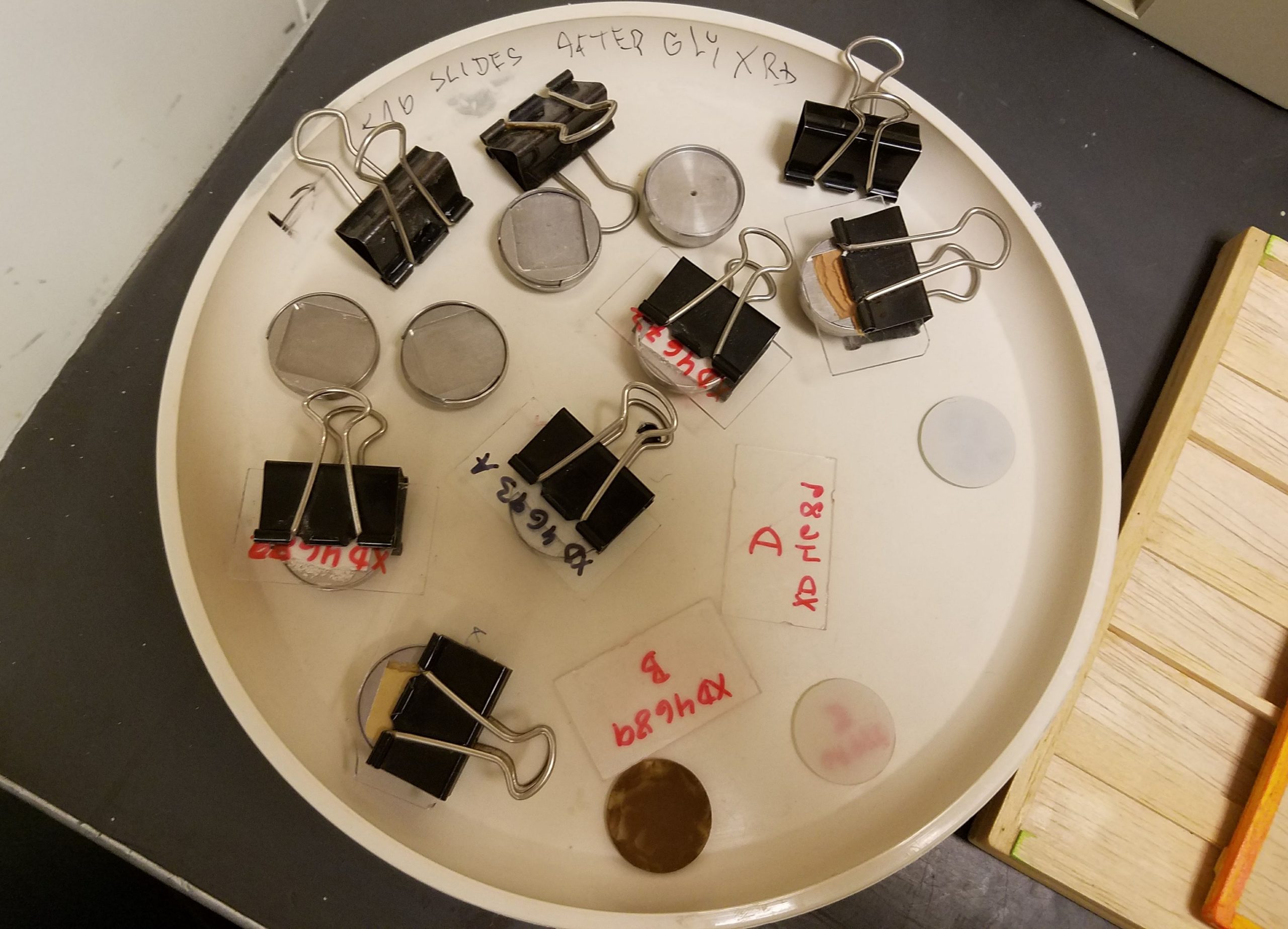

10 – 15 g of the sample (< 250 μm) is immersed in deionized water and disaggregated. The sample is stirred in an electronic mixer to isolate clays in suspension. The particles settle, and the salts that remain in solution are poured off. The sample is stirred again and allowed to settle until only the < 2 μm particles are in suspension. Using an eye dropper, the < 2 μm clays are placed onto a glass slide which is then air-dried, glycolated, and scanned by XRD. Step-scanned data is collected from 2° to 34° 2θ with a fixed rate of 1° per minute with a step size of 0.02°2θ.

Results

Semi-quantitative clay mineral analysis; comparing only the amount of clay minerals in the sample relative to each other.

< 16 μm Clay Mineral Analysis (16CLAY)

Used for identification and relative comparison of clays within sandstone samples.

Recommendation

- 20 – 30 g of a dry powdered sample of < 250 μm size fraction is preferred. If samples are delivered wet and bulky, additional preparation steps (drying, grinding, or sieving) prolong the analysis.

- The average turnaround time for 16CLAY analysis is three weeks per 10 samples.

Methodology

20 g of the sample (< 250 μm) is rinsed with bleach to remove oil (if in an oil-bearing unit). The sample is immersed in acetic acid to dissolve carbonates. The sample is stirred to bring clays into suspension for extraction. The clays are centrifuged and smeared onto a glass slide. To identify clay minerals, the sample is glycolated, scanned by XRD, heated to 350 °C for 1 hr, and rescanned by XRD. Step-scanned data is collected from 2° to 34º 2θ with a fixed rate of 1° per minute with a step size of 0.02°2θ.

Results

This provides two sets of data:

- The first set provides semi-quantitative clay mineral analysis which compares the amount of clay minerals relative to each other.

- The second set provides semi-quantitative mineral percentages of the expandable clays in the sample.

X-ray diffraction analysis is performed employing the instrument calibration verified by NBS and NIST standard reference samples (e.g. Si XRD NBS standards #640 and #640a), in addition to unique mixtures of standards that are implemented for custom applications to ensure analytical accuracy and precision.

The XRD lab is a participant in interlaboratory quality assurance efforts, including the biannual Reynolds Cup organized by the Clay Mineral Society.

XRD Lab Standard Mixtures

For QA/QC purposes, the XRD lab prepares standard mixtures from clay minerals (smectite, illite/smectite, kaolinite, chlorite, and illite) and non-clay minerals (quartz, dolomite, calcite, feldspar, siderite, marcasite, pyrite, etc.), all common mineral phases that occur in sediments, clay ores, and soils. Source material for clay minerals used in standard mixtures are prepared and purified by the Source Clays of the Clay Mineral Society. Additional QA/QC standards are chosen from the suite appropriate RM and NIST standards. These standard concentrations are well known and historically reported, making them essential for QA/QC evaluation of quantitative, semi-quantitative, and Rietveld methods.

The Reynolds Cup

The Reynolds Cup competition was established in 2000 and named after Prof. Robert C. Reynolds, Jr., a pioneer in quantitative clay mineralogy and a great contributor to clay science. It is a quantitative mineralogical analysis competition that is free and open to any laboratory in a commercial, industrial, government, and academic field. It is held by the Clay Minerals Society and organized every two years by the winner of the previous event. Each participant is sent three mixtures of pure standards representing realistic sedimentary rock compositions and can use any method or combination of methods to obtain the most accurate quantitative phase analysis. It is an effective evaluation of various XRD methods applied to clay mineral-bearing samples. Our XRD laboratory is honored to participate in the 10th Anniversary of the Reynolds Cup competition.

X-Ray Fluorescence (XRF)

A non-destructive method suitable to analyze the elemental composition of the object’s surface.

Recommendation

- For best results, the surface of the sample should be as flat as possible with a maximum diameter of 12 in and thickness of 3 ½ in. The ideal shape of specimen dimensions 1 1/8 in (diameter) and 3 ½ in (thickness).

- The average turnaround time is two weeks per 10 samples.

Methodology

The sample’s surface is cleaned with ethanol. The sample is then placed into the XRF spectrometer sample chamber above the X-ray source window and measured under an air atmosphere. If possible, scans are obtained from different areas of the sample.

Results

Semi-quantitative analyses are obtained using Rigaku’s RPF-SQX (Rigaku Profile Fitting-Spectra Quant X) software combine with the FP (fundamental parameters) method. The LLD or LOD are determined by the software. The final report includes the content of Na, Mg, Al, Si, P, S, K, Ca, Ti, Mn, and Fe oxides in wt. percentages, and concentration of other elements in ppm.

PA is a non-destructive method, suitable to analyze the elemental composition of powdered samples.

Recommendation

- 7 – 10 g of a dry powdered sample of < 250 μm size fraction is preferred. If samples are delivered wet and bulky, additional preparation steps (drying, grinding, or sieving) prolong the analysis, and an extra charge is applied (see the XRF Sample Preparation rate on the Pricing, Billing, and Payment page).

- The average turnaround time is two weeks per 10 samples.

Methodology

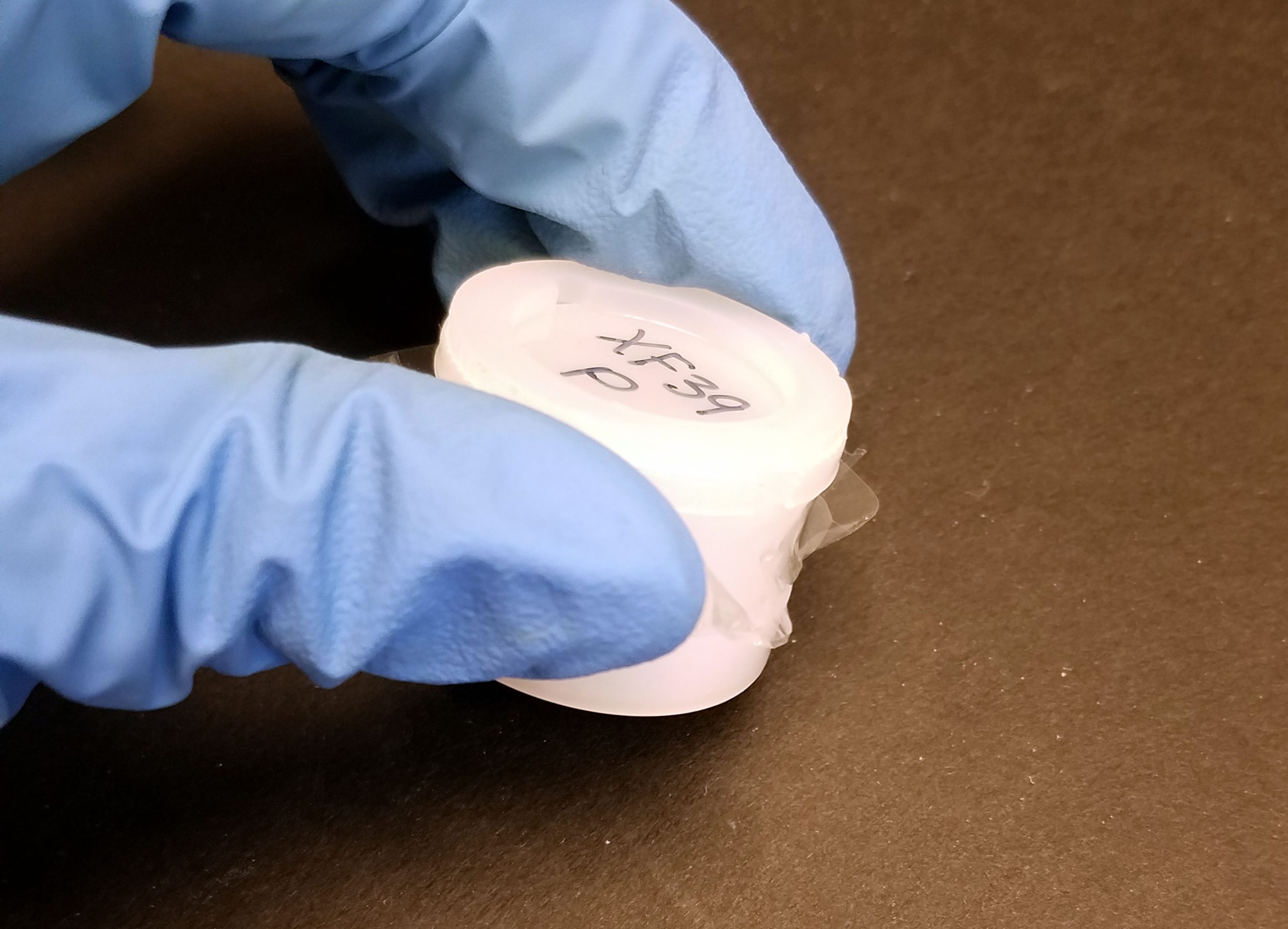

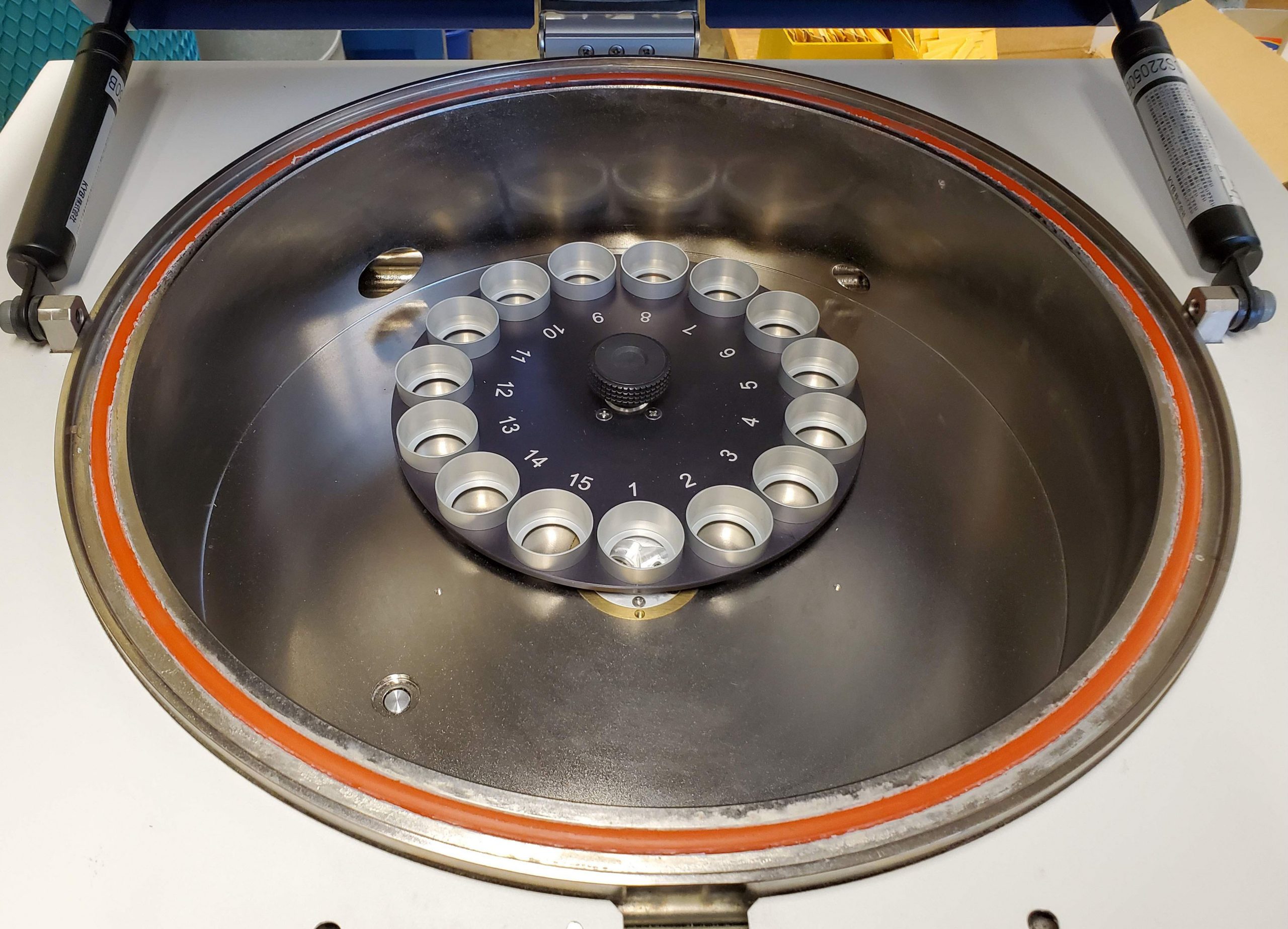

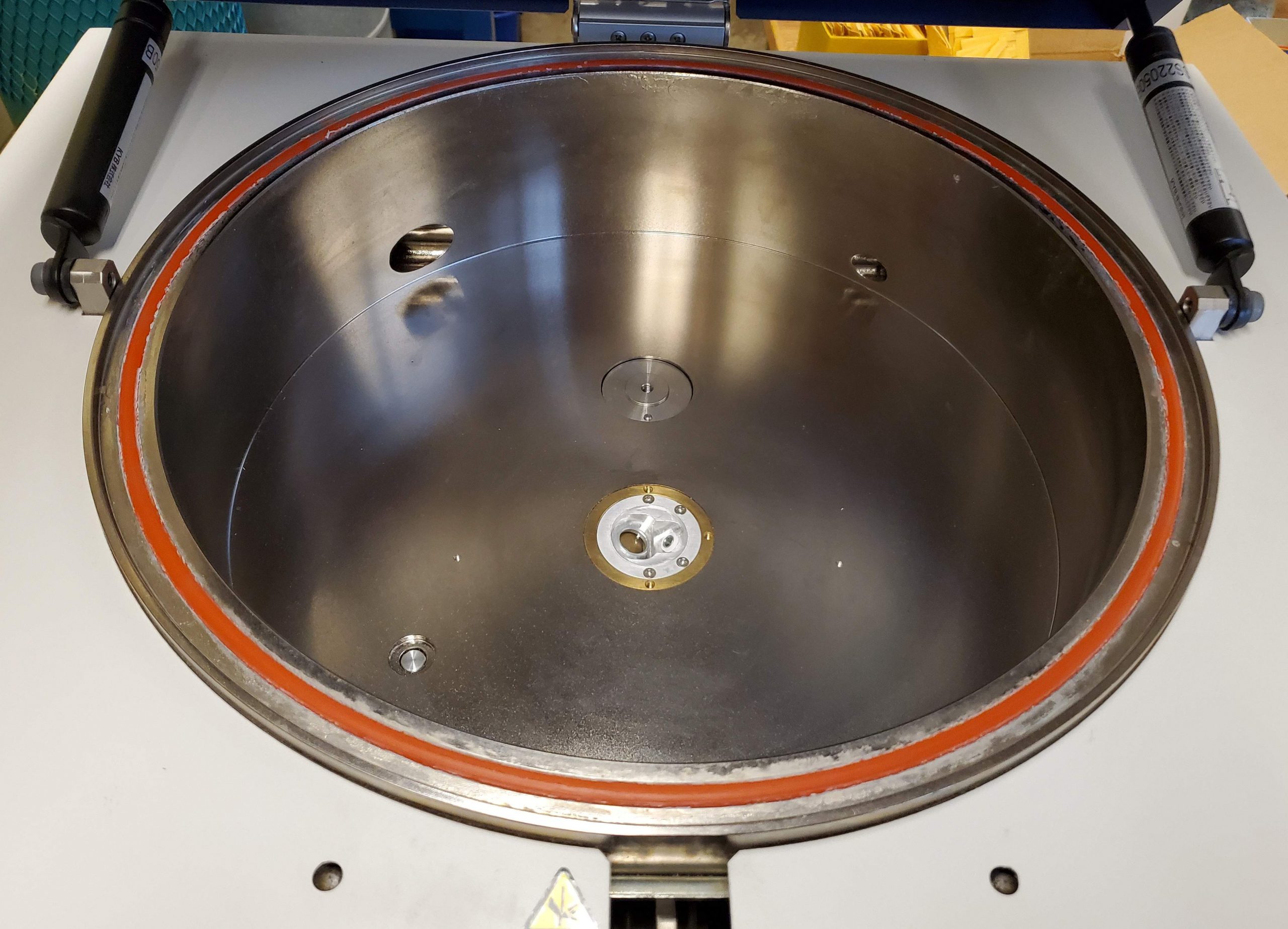

The sample is dried at 105 °C overnight and sieved to < 250 μm. 4 g of the sample is weighed and placed into a Chemplex Industries, Inc. TrimLess® Sleeved sample cup (Cat # 1330) fitted with a Chemplex Industries, Inc. Prolene® film (Cat # 426). Samples cups are analyzed by a Rigaku NEX CG Energy-Dispersive X-Ray Fluorescence (EDXRF) spectrometer equipped with an automatic sample changer that accommodates 13 specimens and 2 standards under ultra-high purity helium atmosphere.

Results

Semi-quantitative analyses are obtained using Rigaku’s RPF-SQX (Rigaku Profile Fitting-Spectra Quant X) software combine with the FP (fundamental parameters) method. The LLD or LOD are determined by the software. The final report includes the content of Na, Mg, Al, Si, P, S, K, Ca, Ti, Mn, and Fe oxides in wt. percentages, and concentration of other elements in ppm.

Quality Assurance (QA) and Quality Control (QC)

Precision and accuracy are determined by analyzing sample duplicates as well as certified reference materials from the National Institute of Standards & Technology (NIST).

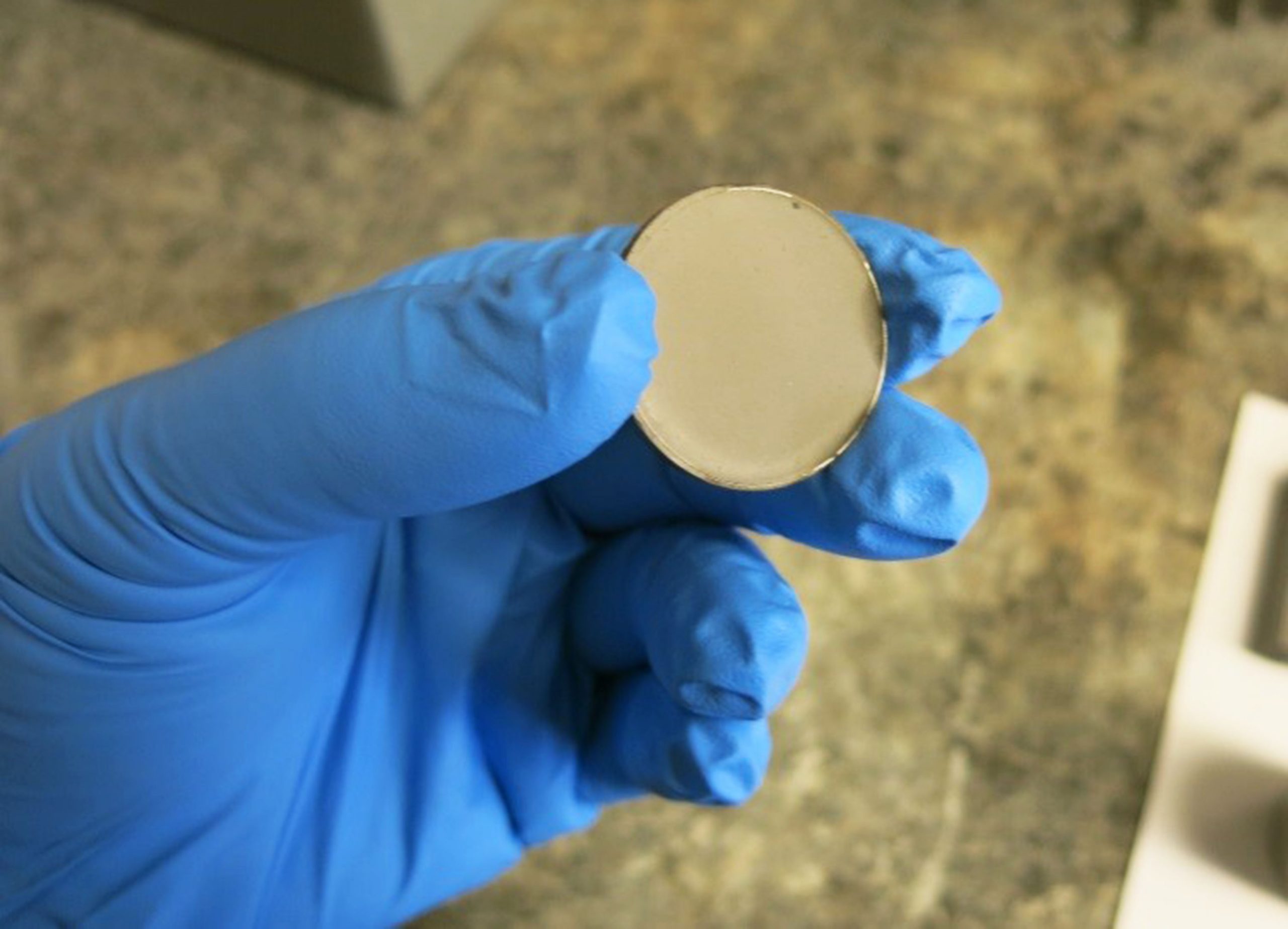

PP method is suitable to analyze the elemental composition of pelletized samples with flat surface area to obtain higher accuracy.

Recommendation

- 7 – 10 g of a dry powdered sample of < 250 μm size fraction is preferred. If samples are delivered wet and bulky, additional preparation steps (drying, grinding, or sieving) prolong the analysis, and an extra charge is applied (see the XRF Sample Preparation rate on the Pricing, Billing, and Payment page).

- The average turnaround time is two weeks per 10 samples.

Methodology

The sample is dried at 105 °C overnight and sieved to < 250 μm. The sample is mixed with the SPEX paraffin binder 3646 (9:1 ratio) in a Chemplex Industries, Inc. SpectroVial Grinding Vial (Cat # 1134) with two Chemplex Industries, Inc. Ball Pestles (Cat # 1211) using a SPEX mixer mill. 4 g of the mixture is hydraulically pressed into a 32 mm pellet at 10 tons of pressure and analyzed by a Rigaku NEX CG Energy-Dispersive X-Ray Fluorescence (EDXRF) spectrometer under vacuum. The automatic sample changer accommodates thirteen specimens and two standards.

Results

Semi-quantitative analyses are obtained using Rigaku’s RPF-SQX (Rigaku Profile Fitting-Spectra Quant X) software combine with the FP (fundamental parameters) method. The LLD or LOD are determined by the software. The final report includes the content of Na, Mg, Al, Si, P, S, K, Ca, Ti, Mn, and Fe oxides in wt. percentages, and concentration of other elements in ppm.

Quality Assurance (QA) and Quality Control (QC)

Precision and accuracy are determined by analyzing sample duplicates as well as certified reference materials from the National Institute of Standards & Technology (NIST).

Preparation step is used when samples do not meet the EDXRF sample criteria: a) dried at 105 °C; b) < 250 μm size powder fraction.

Methodology

10 g of sample is disintegrated in an agate dish and placed into an oven at 105 °C overnight. The sample is ground using a Spex zirconia ceramic vial grinding set in a Spex ball mixer-mill and sieved to pass 250 μm.